Engineering Capabilities

Multi-disciplinary Engineering for Innovation

Innovative Engineering Design for Science & Industry

At Sector Technology we offer comprehensive, multi-disciplinary, engineering design solutions

Tailored Solutions to Meet Your Needs

From Concept to Creation

Advanced Techniques for Optimal Performance

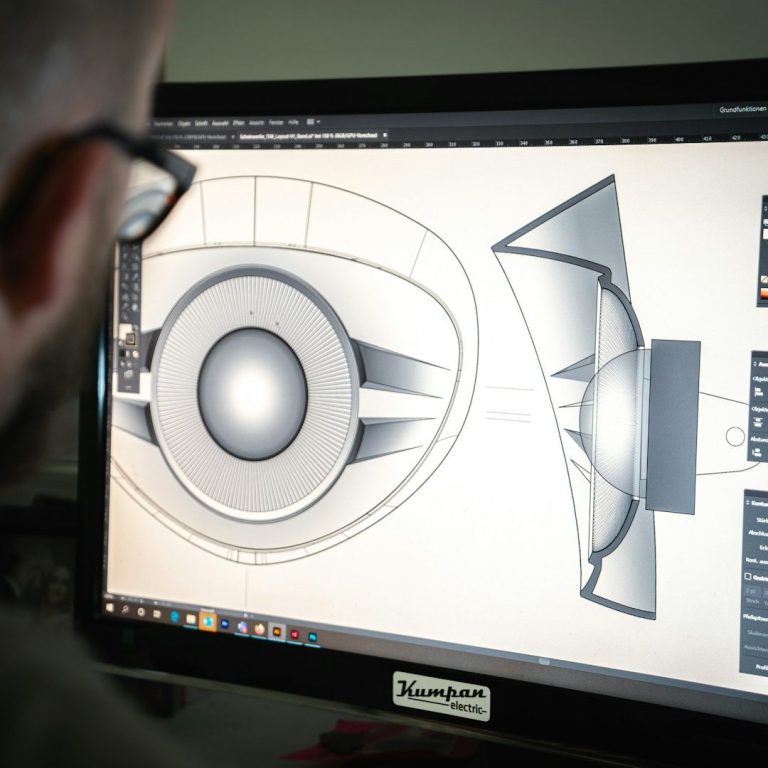

Industrial Design Integration

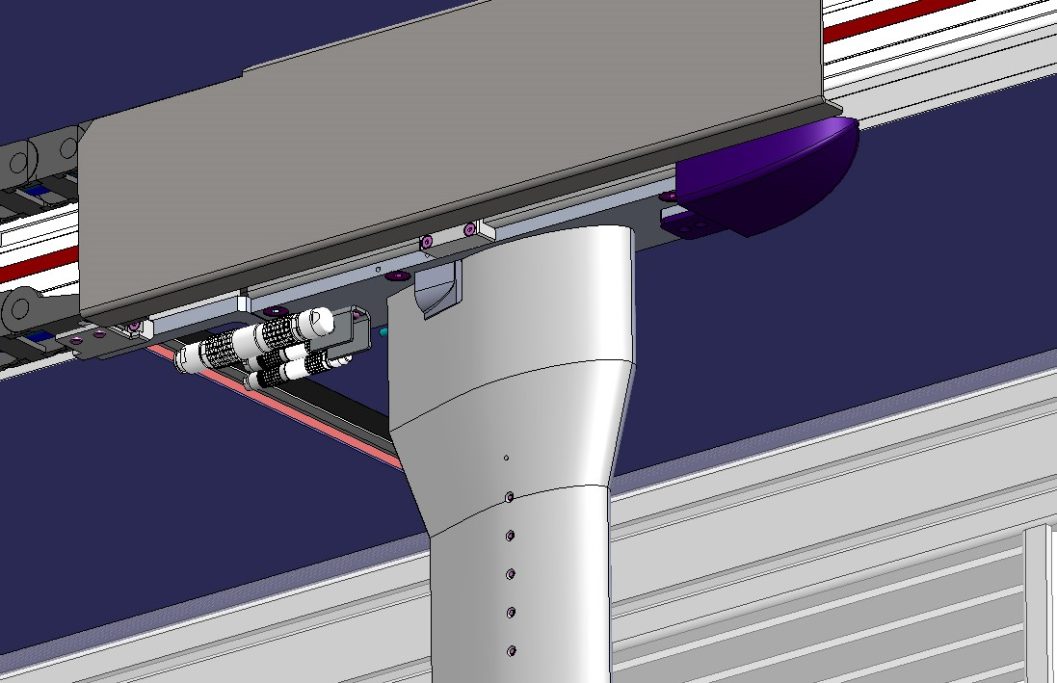

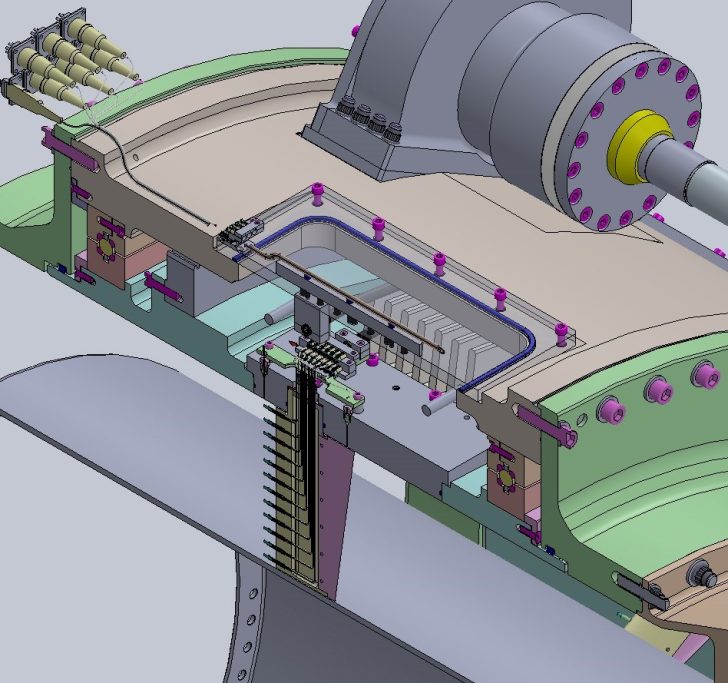

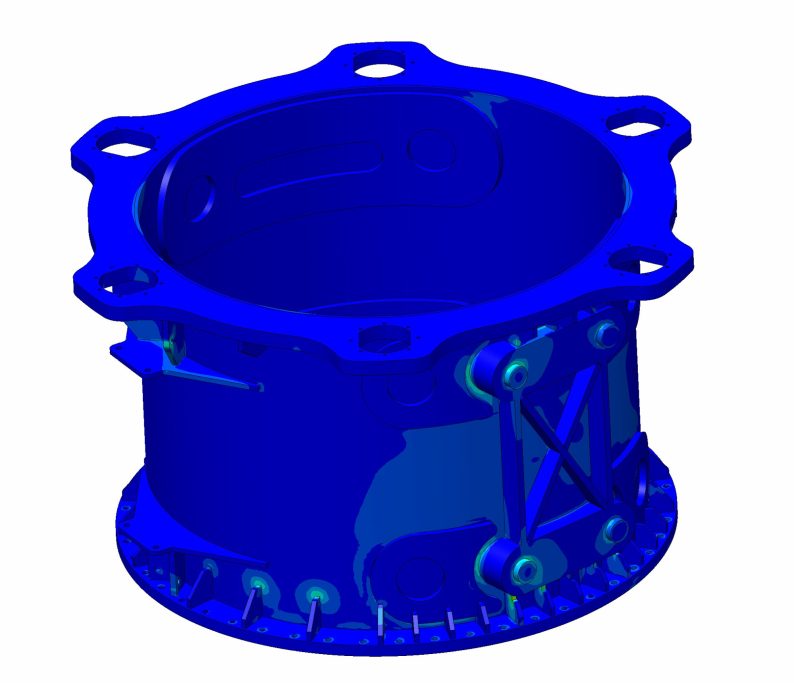

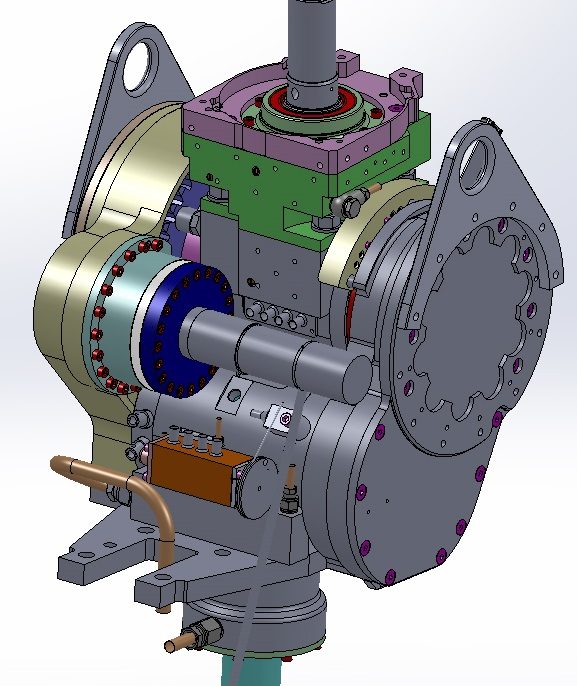

Mechanical Design

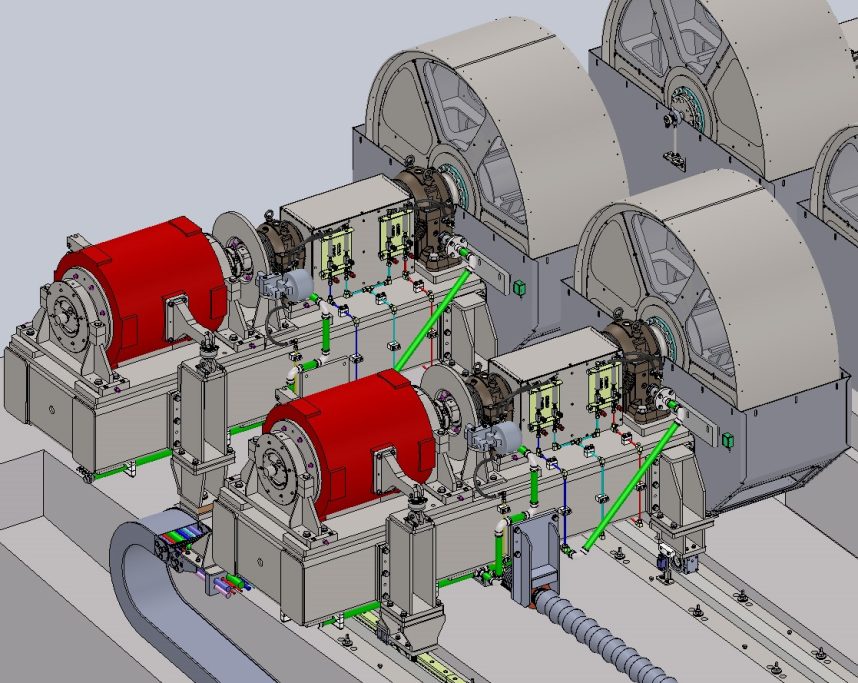

Sector Technology has significant experience of providing innovative solutions to complex technical problems for a large variety of advanced engineering products and machines, using a multi-disciplinary approach. This is based around 3D Mechanical Engineering Design (CAD), Stress & Vibration Analysis, FEA, Fluid Mechanics, CFD, Heat Transfer, Electronics, Instrumentation and Control & DAQ software skills. Typical product and equipment areas include:

- Aerospace Equipment, Structures and Propulsion

- Rail & Automotive Vehicles and Equipment

- Life Science, Medical & Healthcare Products

- Turbomachinery & High Speed Rotating Equipment

- Advanced Scientific Instruments

- Consumer & White Goods

- Special Purpose Machines and Test Equipment

- Robotic Traversing Equipment and Products

- Wind Tunnels and Wind Tunnel Equipment

- Data Acquisition & Control Systems

Our 3D CAD system forms the backbone of our advanced engineering analytical capability, by integrating directly with our Finite Element Analysis software, for stress and vibration analysis, as well as for our Computational Fluid Dynamics analysis. This enables us to offer a very rapid, integrated, cost-effective and comprehensive design optimisation capability.

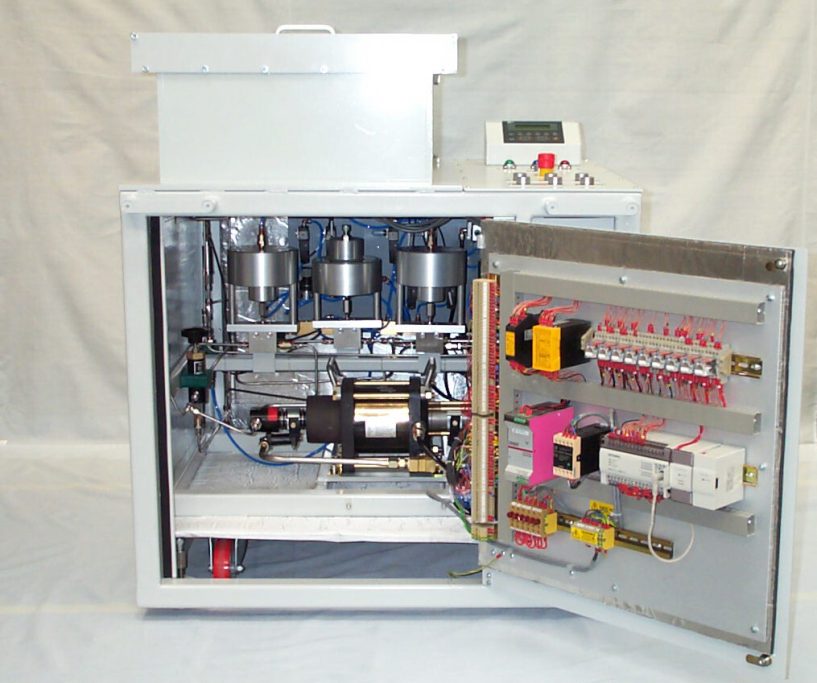

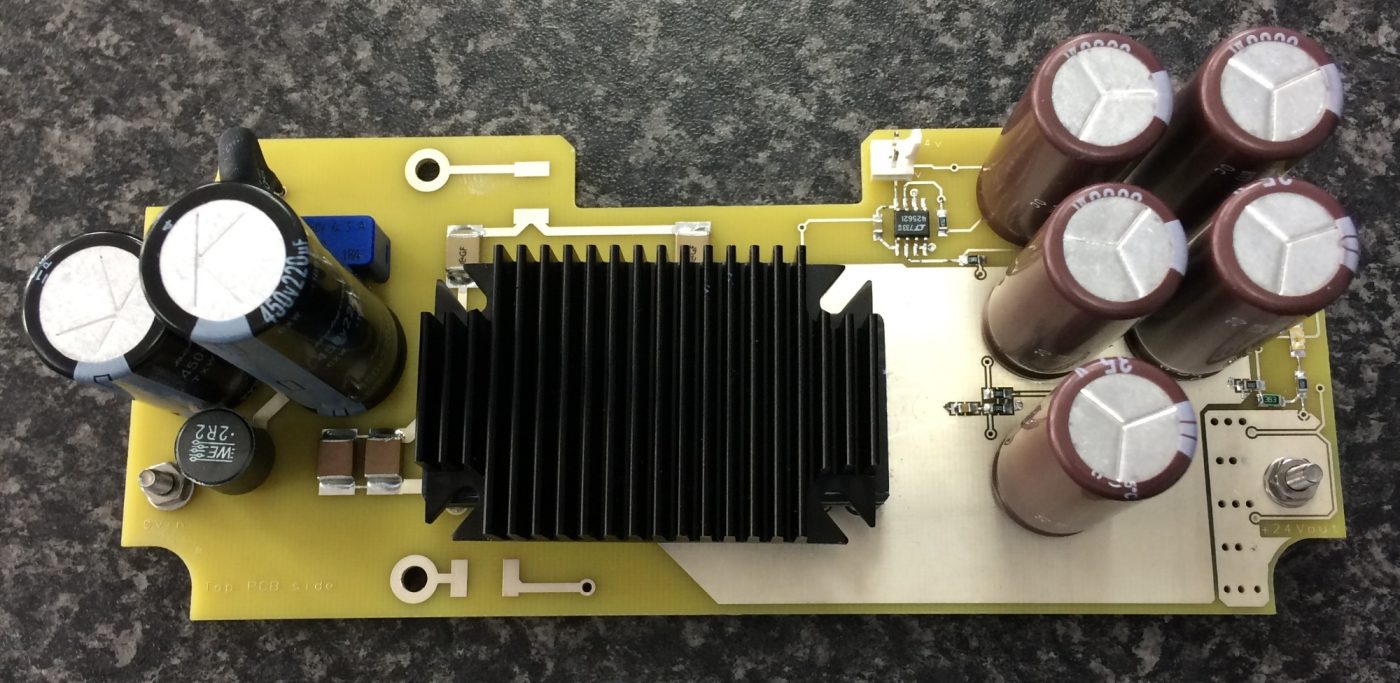

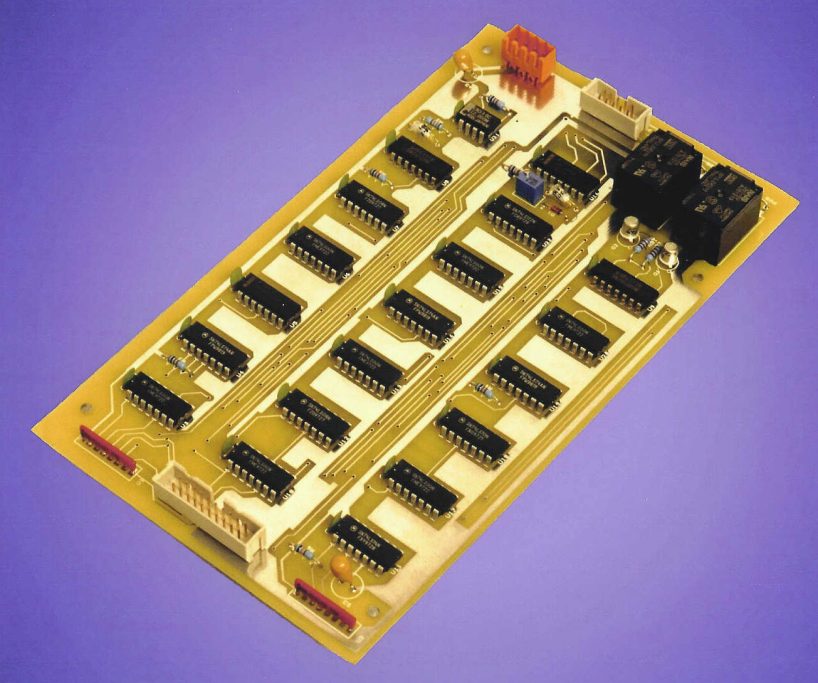

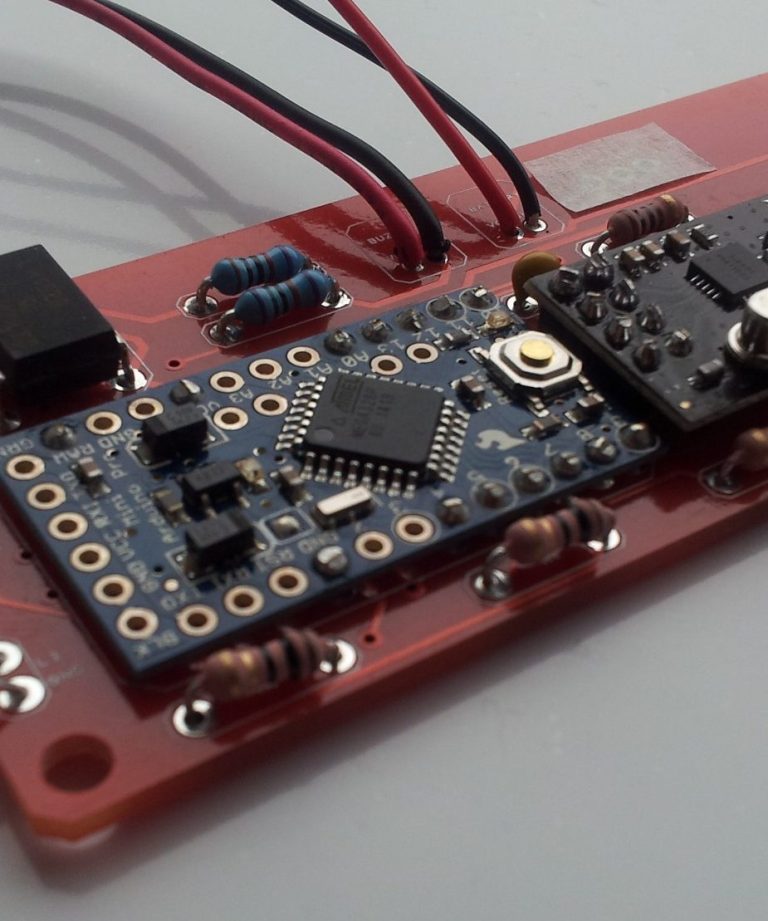

Electrical & Electronic Design

Today, all advanced technology products and equipment require some degree of electronics/electrical design, or use of micro-controllers, PLC Control and/or PC Data Acquisition & Control Systems. Sector Technology is able to offer a significant capability in this area for advanced technology development applications. This can vary from standard electrical cabinet design to PCB design for integration of control, or using PCs & PLCs for Data Acquisition and Control.

PCB CAD Design

As mentioned above, to supplement our mechanical and electrical engineering design capability, we also undertake the design of PCBs as part of a product design/development project or as part of a piece of machinery or equipment we produce. For this we have the capability to design multi-layer boards using through hole or Surface Mount Technology.

National Instruments Hardware

National Instruments equipment is used on a wide range of engineering projects as the primary Data Acquisition hardware. Sector Technology has significant experience in its use to undertake complex data acquisition tasks.

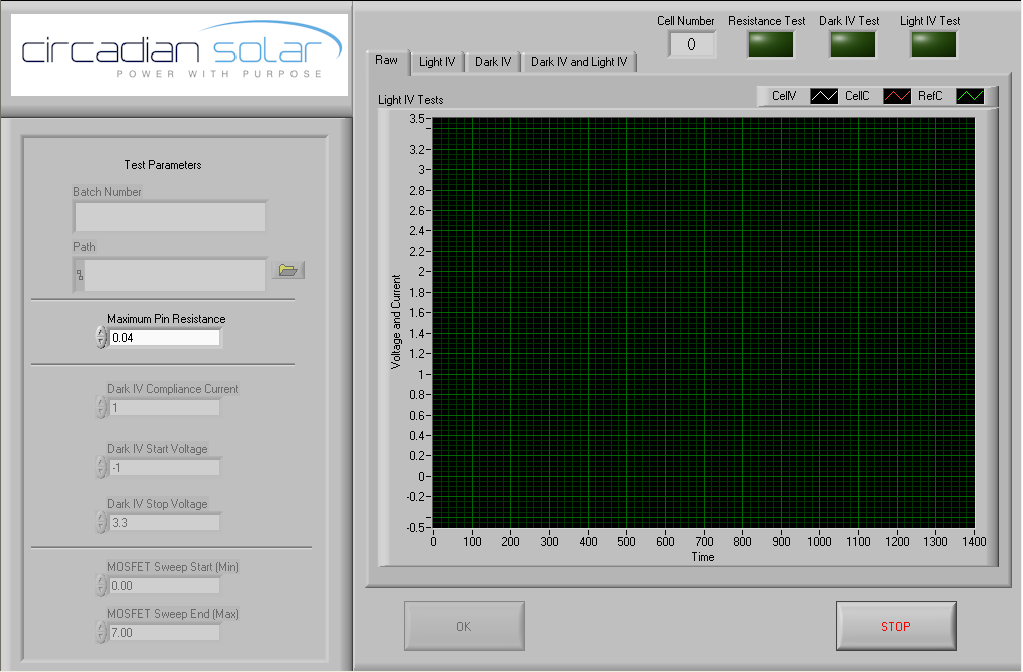

DAQ & Control Software

National Instruments 'LabVIEW'

National Instruments 'LabVIEW' is one of industry's main Data Acquisition, Manipulation and Control design software packages. Sector Technology has significant experience in the use of 'LabVIEW' for DAQ applications, with typical capabilities and examples involving:

- Identify Data Acquisition & Control requirements

- Specify Instrumentation & DAQ/Control Hardware

- Specification of Industrial PC system

- Identify & produce Main Control Screens & Code

- Produce Support Documentation

- Software Support & Upgrades

- Data Acquisition & Control of Pressure Rigs

- Data Acquisition for Electro-pneumatic Rigs

- Data Acquisition and Control of a Precision Electro-mechanical Test Rigs

- Data Acquisition of Automated Testing Machines

- Data Acquisition for Process Control

- Control of multi-axis Robotic Traverse Systems

PLC Control

Sector Technology also has significant experience of PLC control systems using, principally, Mitsubishi and Siemens PLCs. Relatively small PLCs with less than 30 I/O are used on simple control systems for small semi-automated workstations, or larger +100 I/O systems for the control of complex machines with multiple data, control and safety requirements. These may often have their own HMI, or be coupled to a customised display option.

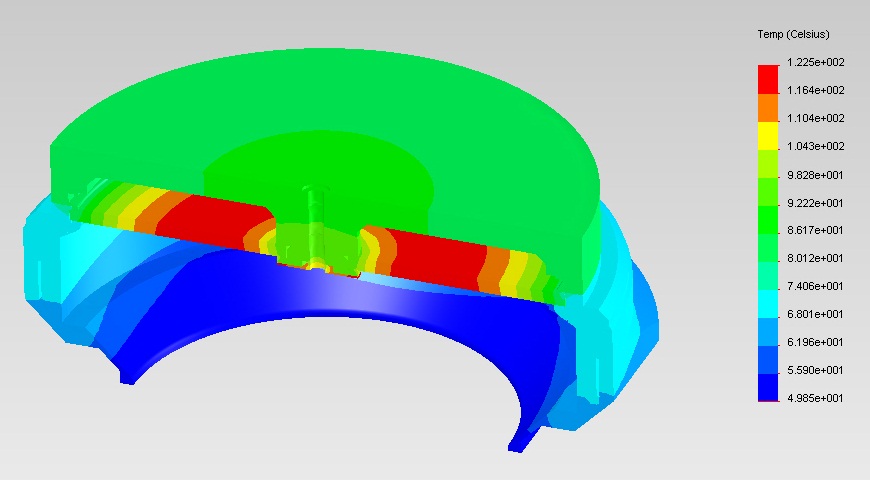

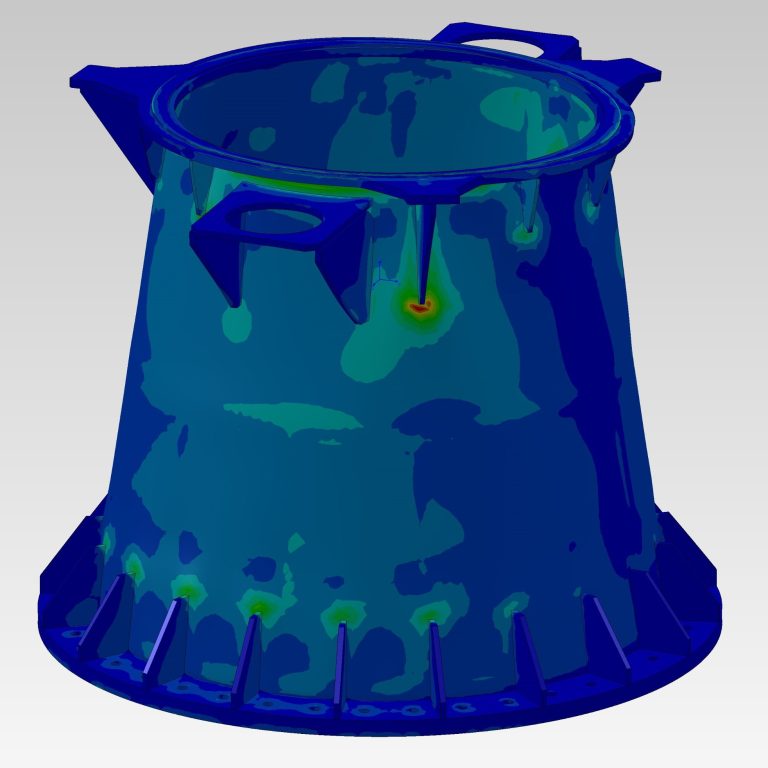

Mechanical Integrity

Stress, Vibration Analysis & FEA

Stress and vibration analyses are essential to achieve the required product integrity whilst avoiding costly and lengthy development testing. Sector Technology is able to offer a comprehensive capability in this area using a wide variety of classical analytical tools, such as:

- Steady State & Transient Stress Analysis

- Buckling & Impact Analysis

- Low Cycle & High Cycle Fatigue, Creep Analysis

- Vibration Modal Analysis of Structures

To support this, 3D Finite Element Analysis can be undertaken for more complex analyses and geometry, so increasing accuracy, reducing cost and resulting in a more optimised design. Typical FEA undertaken are:

- Linear & Non-Linear Static Analysis

- Steady State and Transient FEA

- Thermal Stress Analysis

- Fatigue & Creep Analysis

- Modal Frequency Analysis & Response

- Buckling & Impact Analysis

Rotordynamics Analysis

For high speed rotating equipment, e.g. turbomachinery, rotordynamics analysis is a key capability for a successful design. Typical analysis areas are:

- Critical Speed Mapping & Strain Energy Analysis

- Critical Speed Control & Damping System Design

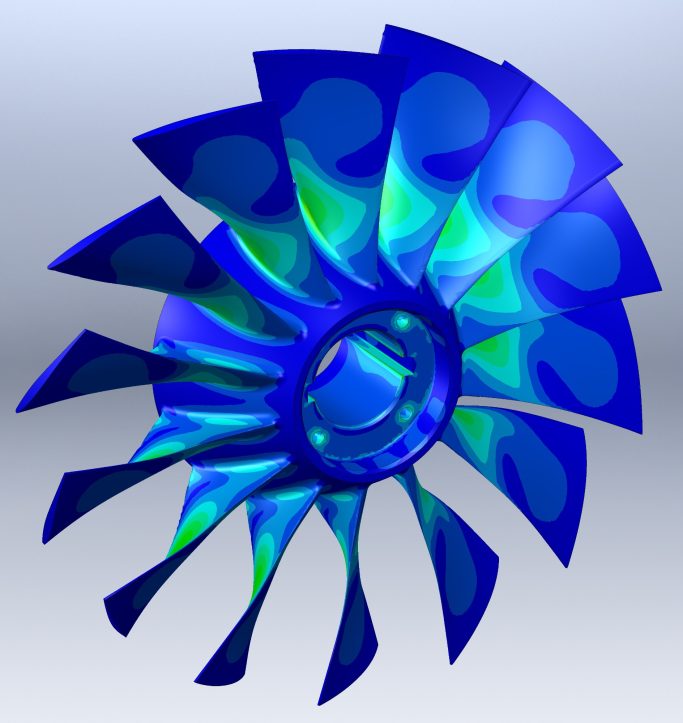

Fluid Mechanics, Heat Transfer & CFD

Fluid Mechanics, Thermodynamics & Heat Transfer

Sector Technology has a wide range of fluid mechanics & heat transfer experience in such diverse fields as space vehicle applications, wind tunnel equipment, turbomachinery, heat exchangers & electronics etc. Analyses are carried out using both classical techniques with bespoke software and Computational Fluid Dynamics. Typical areas of analysis are:

- Aerodynamic & Hydrodynamic Fluid Flow

- Heat Transfer & Cooling Analyses

- Steady State and Transient Analyses

- Turbomachinery Analyses

- Machine Fluid Systems Analysis

- Heat Transfer Coefficient calculation

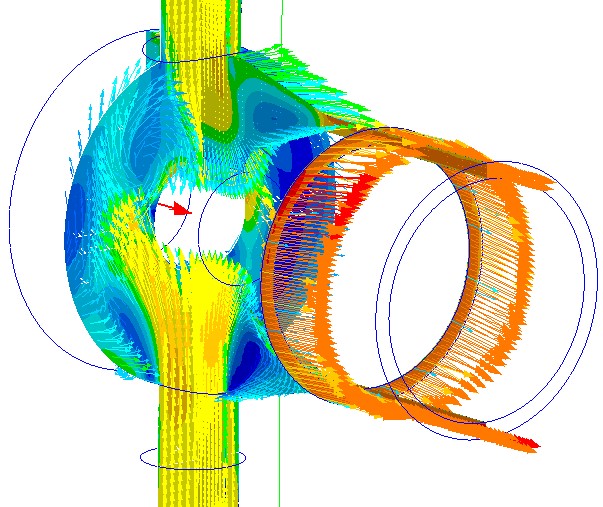

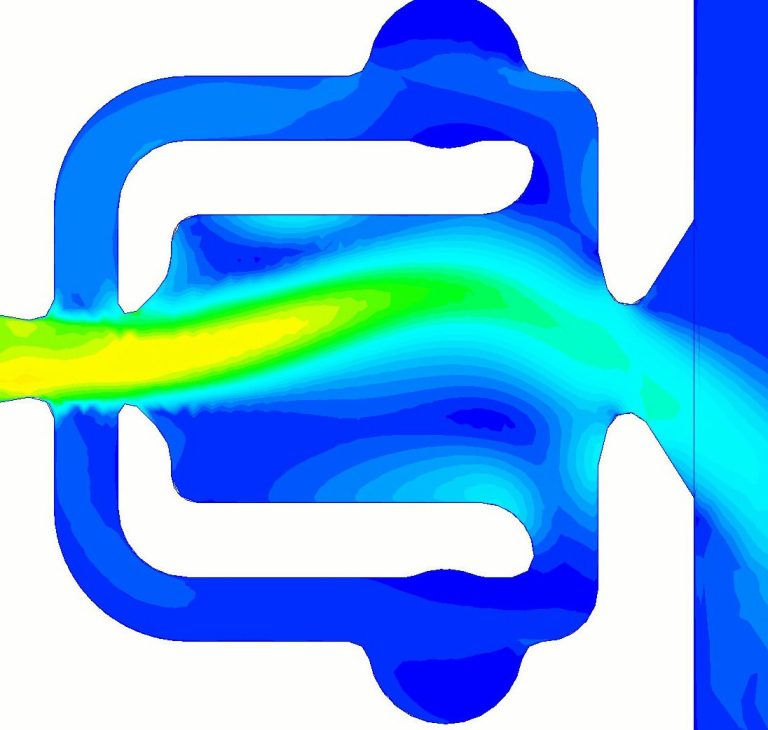

Computational Fluid Dynamics Analysis

With the advent of 3D CAD & PC based CFD software, CFD can be applied to a far broader range of products than ever before. When further coupled with 3D FEA software, this gives a comprehensive design optimisation capability. Typical CFD analysis capabilities are:

- Laminar, Turbulent, Internal & External Flow

- Incompressible and Compressible Flow

- Transonic/Supersonic Flow

- Steady State and Transient Analysis

- Two Phase Flow

- Conduction, Natural and Forced Convection HT

- Radiation Heat Transfer & View Factor calculation

- Electronics Heat Generation & Cooling Analysis

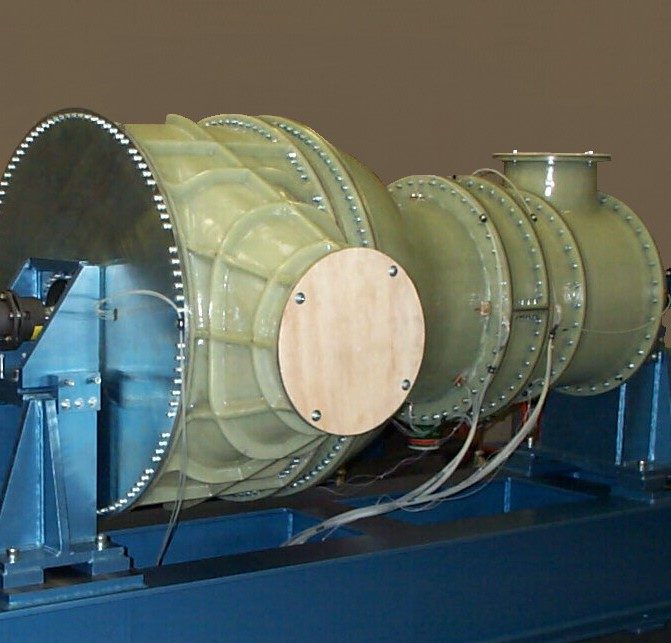

Composite Design & Analysis

Advanced glass, aramid and carbon composites have many advantages over conventional materials in advanced, high performance products such as wind turbines, gas turbines, energy storage, high speed machinery, robotic applications & prosthetics. In addition, they also offer unique and tailored physical properties due to their laminate structure and the ability to conform to complex geometries, thus making them an ideal choice for many new applications.

Sector Technology has the capability to design, analyse and manufacture composite structures as one of our key technologies and integrate these composite structures into the rest of the overall product design. This capability is based on the following:

- SolidWorks 3D CAD for product and tooling design

- Laminate assessment software to investigate and optimise different potential laminate structures

- Finite Element Analysis for overall structural and thermal analysis

- Sub-contract composite manufacturing network for a variety of materials and manufacturing processes

- Digitising of existing parts with complex geometry

- Design experience of multiple, different GFRP & CFRP structures

Our experience has always been focused on innovative solutions, for high stiffness, mass critical products using composite materials technology where there is a significant advantage to do so.

©Copyright Sector Technology Ltd. All rights reserved.

We need your consent to load the translations

We use a third-party service to translate the website content that may collect data about your activity. Please review the details in the privacy policy and accept the service to view the translations.