Products & Equipment Solutions

Developing solutions for advanced technology products and equipment

Tailored Solutions for your Products & Equipment

Custom Solutions for Unique Challenges

Complex Precision Engineered Products

Collaborative Approach to Design & Development

Commitment to Engineering Quality and Reliability

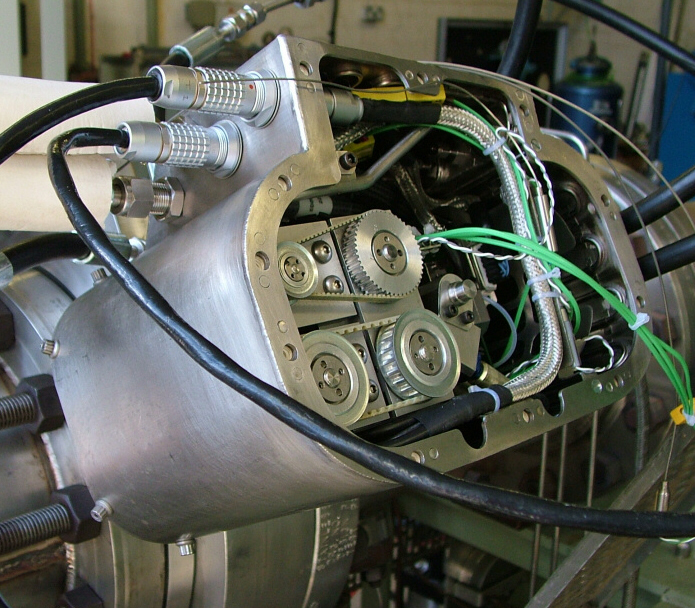

Aerodynamic & Turbomachinery Equipment

Sector Technology’s background in gas turbines, electro-mechanical design, analysis and their associated test rigs and instrumentation, enables us to design and manufacture (D&M) a wide range of products for the Aerodynamic & Turbomachinery Equipment market. Our experience includes projects for a range of typical equipment categories and examples as follows:

- Design & Manufacture (D&M) of Instrumentation, Gas Turbine Probes & Traversing Systems

- D&M of Turbomachinery Test Rigs & Automated Test Equipment - PC & PLC control

- D&M of Scaled Wind and Water Turbine Test Rigs

- D&M of Flow Test Equipment

- Data Acquisition/Instrumentation Systems using NI 'LabVIEW'

- Gas Turbine Inlet Temp/Pressure Rake Assembly

- Turbine Rig Total Temperature and Total Pressure Instrumentation Rakes & multi-hole Probes

- 300 kW Contra-Rotating, Statorless Turbine Rig

- VAWT 1.6 m dia. Prototype Test Demonstrator

- 8 m dia. VAWT Demonstrator Shaft Drive Assy

- 210 kW, 80 m/s Wind Tunnel Fan

- Gas Turbine Combustor Rotary Traverse

- High Temp. 2 Axis Gas Turbine Traverse System

- Turbine Rig Circumferential Traversing System

- Prototype Water Turbine Test Demonstrator

- 30,000 RPM High Pressure Helium Circulator

- 63,500 RPM WT Model Turbofan Propulsion Simulator

Some of these ‘Case Studies’ are available on request.

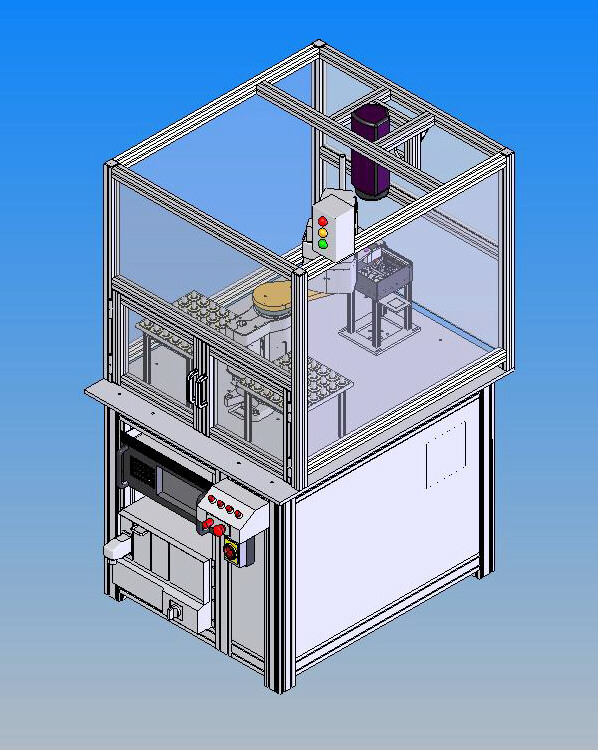

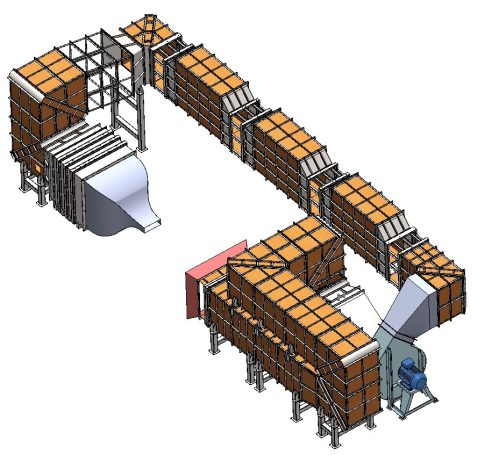

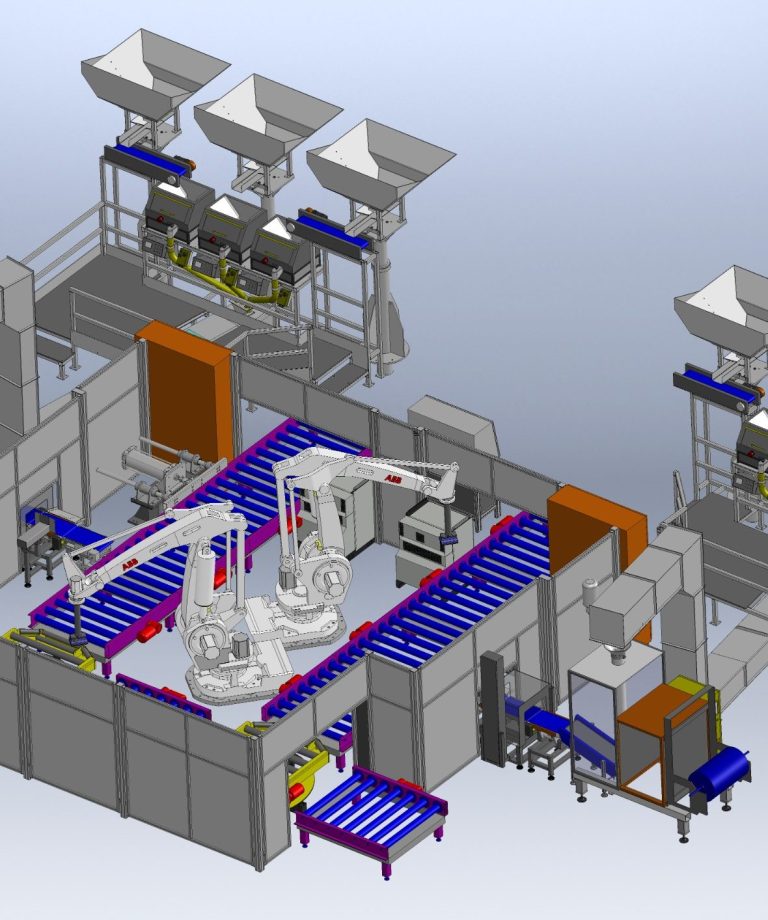

Automation & Robotics

With our expertise in electro-mechanical motion systems design, sensors and PC & PLC control and data acquisition, Sector Technology is able to design and manufacture (D&M) a broad range of Automation & Robotic Workstations. These can be used for both Production and Development Testing environments, using a wide range of pneumatic, hydraulic, electrical actuators and industrial robots. Further, with our structural design and mechanical integrity capability, we have the capability to design bespoke Robotic Arms for specific applications.

Typical types and examples of applications are as follows:

- D&M of Automation Assembly Equipment

- D&M of Automated Test Equipment (ATE)

- D&M of Robotic Traversing & Positioning Systems

- D&M of Robotic Cell Equipment

- Robot Sensing Instrumentation Development

- PC & PLC Controlled Special Purpose Machines

- Modular Plastic Box Assembly Machine

- Robotic Coin Bagging Line Design

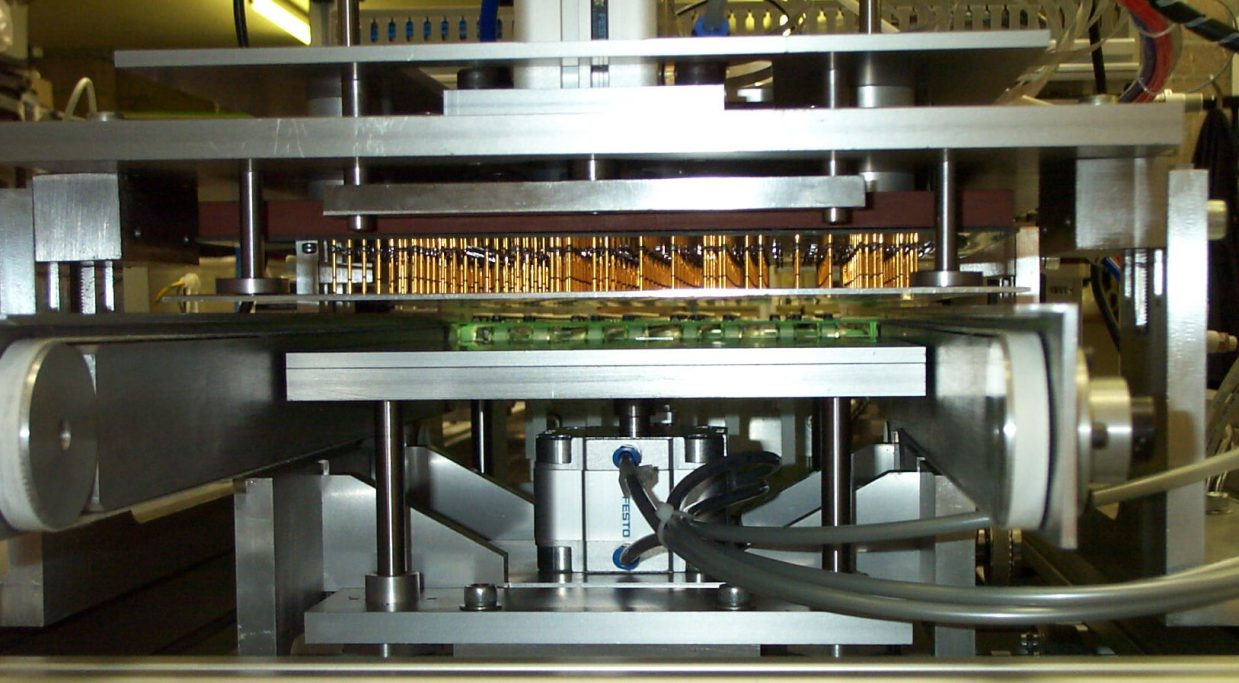

- Automated PCB Test & De-Panelling Machine

- Automated PV Cell Robotic Test Workstation

- Automated Two-Stage Press Feed System

- Automated Air Conditioning System Tester

- Instrument Panel Robotic Flame Treatment Fixture

- Large Fabrication Robotic Automated Welding Fixture

- Semi-Automated Automotive Windscreen Washer Nozzle Test & Alignment Workstation

Some of these ‘Case Studies’ are available on request.

DAQ & Instrumentation

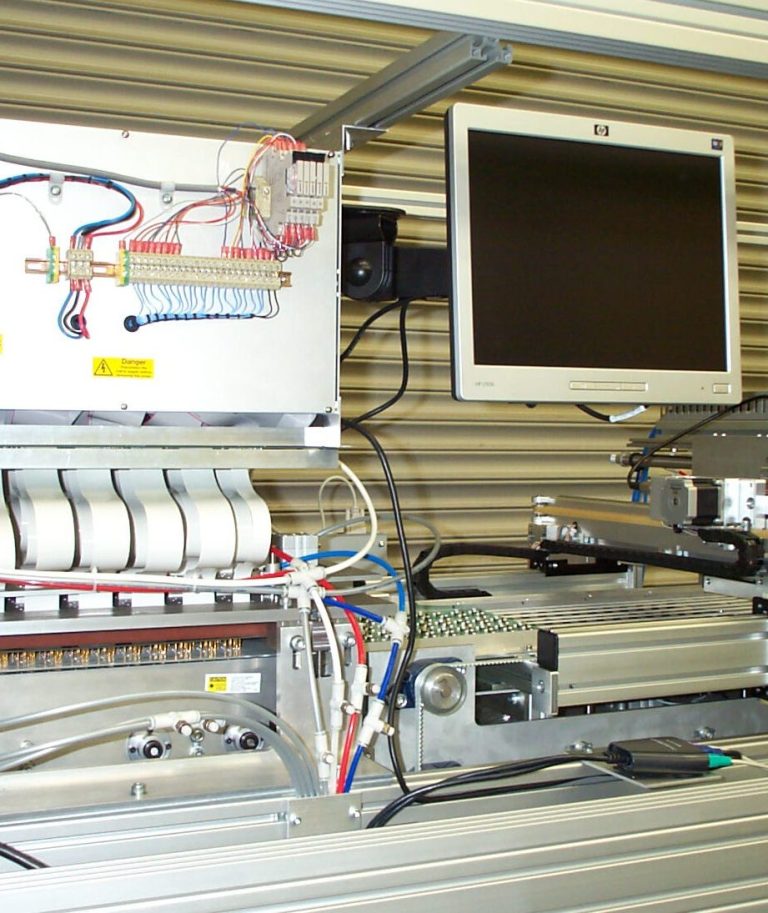

As separate projects in their own right or as a part of a Machine or Test Equipment, Sector Technology can design, build (D&M) and supply Control Systems, Data Acquisition Systems (DAQ) or Instrumentation. Control is usually via a PLC and mounted in a separate electrical enclosure or 19” rack, with its Power Supplies, Safety Relays, PID Controllers, HMI etc. For small, low accuracy DAQ requirements, the PLC itself may also be used. For more complex DAQ, a PC with Industry Standard National Instruments’ ‘LabVIEW’ is used.

Typical types and examples of Control, DAQ Systems & Instrumentation are as follows:

- D&M of Control and DAQ Systems for instruments e.g. speed, position, pressure, temp etc.

- D&M of PLC Control & DAQ Systems

- D&M of PLC Control & PC Based NI ‘LabVIEW’ DAQ Systems

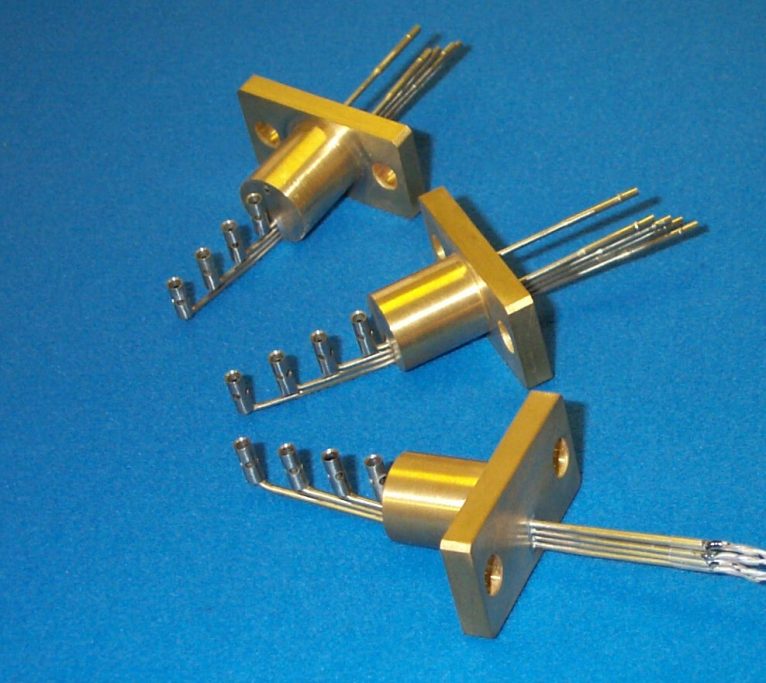

- D&M of Aerodynamic Probes

- D&M of Machine Condition Monitoring Systems

- PC Based ‘LabVIEW’ Control & DAQ System for Pressure Test Rig

- PLC Control and DAQ System for Automotive Brake Test Machine

- PLC Control & PC Based ‘LabVIEW’ DAQ System of an Automated PCB Testing Machine

- PC Based ‘LabVIEW’ DAQ System for Turbine Rig

- PC Based ‘LabVIEW’ Control of Gas Turbine, 2 Axis Probe Traverse

- PLC Control of Heated Low Velocity Wind Tunnel

- Aerodynamic Total Temp & Pressure Rakes

- Gas Turbine Combustor Water-Cooled Gas Sample & Thermocouple Rakes

- Gas Turbine Noise Measurement Rakes

Some of these ‘Case Studies’ are available on request.

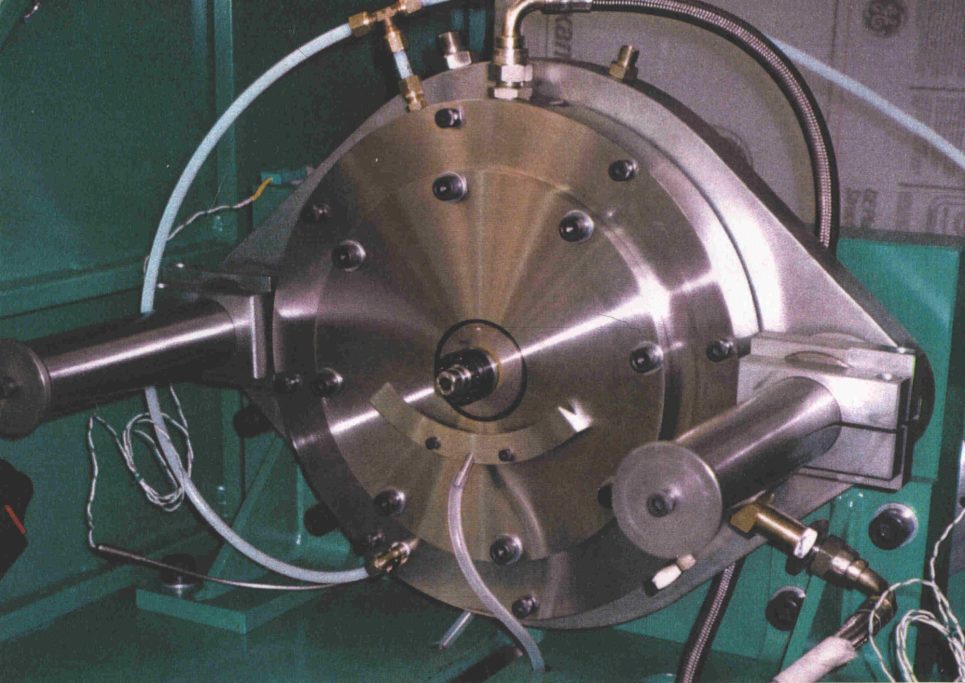

High Speed Rotating Machinery

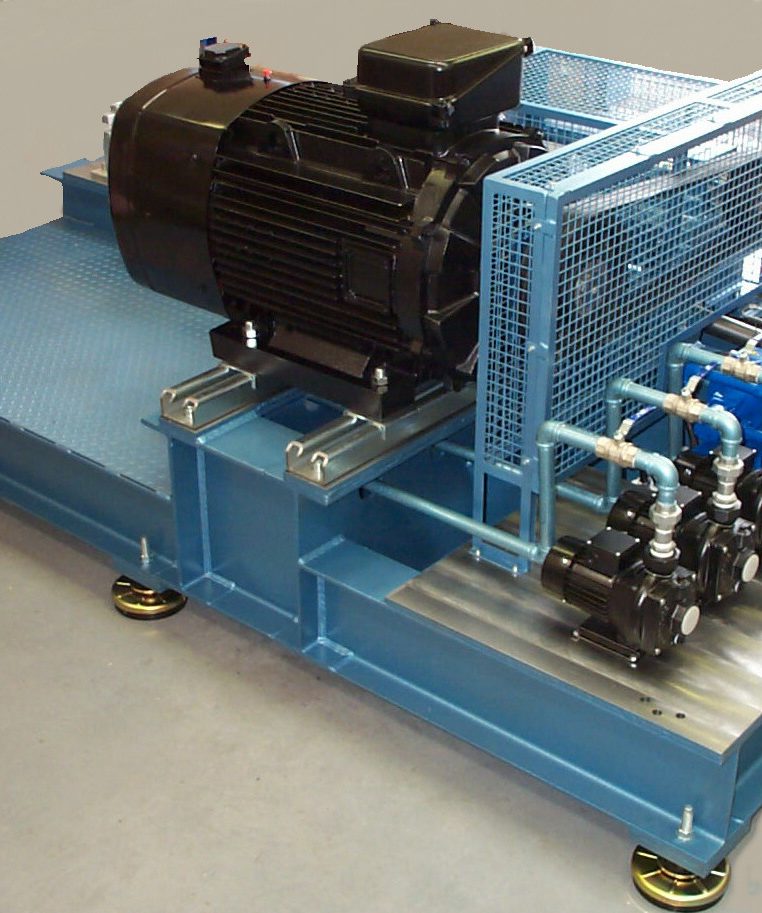

A particular capability of Sector Technology is the design and manufacture of high speed rotating machinery. The design of these systems requires a deep understanding of drive system design, stress & vibration analysis, bearing & lubrication systems and rotor analysis.

Our capability is based on the design and analysis of high speed turbines, compressors & turbine rigs, which require advanced mechanical design and stress & vibration analysis of the blades, discs, support casings and rotor shaft assembly. One key aspect of the design is the shaft system rotordynamics analysis, to ensure acceptable vibration characteristics up to the maximum speed. Sector Technology is one of a few companies that can therefore apply these skills to the design of other types of high speed rotating machinery. Typical equipment categories and examples are as follows:

- Design & Analysis of High Speed Rotating Products, Components & Test Rig Systems

- D&M of +50k RPM Seal & Bearing Test Rigs

- D&M of Compressor & Turbine Test Rigs

- D&M of 100k RPM Spin Rigs

- D&M of High Speed Rotor Damper Systems

- Condition Monitoring DAQ Systems

- 24k RPM Mechanical Seal Test Rig

- 25k RPM F1 Polymeric Seal Endurance Test Rig

- 30k RPM, 110 kW Gas Seal Test Rig

- 30k RPM Aerospace Rotor Spin Test Rig

- Automotive 4 Wheel Dynamometer System

- 6k RPM Large DC Motor Rotor Spin Test Rig

- 102k RPM Bearing Development Test Rig

- EV Motor Test Rigs

Some of these ‘Case Studies’ are available on request.

Special Purpose Machines & Test Equipment

Sector Technology designs, develops and manufactures (D&M) a wide range of Special Purpose Machines and Test Equipment for many market sectors such as industrial, aerospace, automotive, medical, consumer and power generation/renewable. These are typically designed and manufactured for a specific manufacturing process, assembly, test or series of tests, on either individual components, assemblies or complete products. They may be required for new manufacturing or production processes, complex assembly tasks, functional performance & endurance tests, environmental & safety tests or other legal requirement tests. Typical examples of Special Purpose Machines and Test Equipment are as follows:

- D&M of Special Purpose Process Machinery

- D&M of Renewable Energy Equipment

- D&M of Environmental Machinery

- D&M of Special Purpose Test Equipment

- D&M of Automated Test Equipment

- Powder Material Rotary Melt Spinning Machine

- PC based Automated Component Pressure Test Rig

- Automated High Frequency Pulse Test Equipment

- PC controlled Seal Force & Displacement Test Rig

- Electrical Special Purpose Bench Test Equipment

- Automated Brake Pressure, Force and Endurance Test Equipment

- Automated Ignition Key Environmental Test Equipment

- High Pressure & Vacuum Component Fatigue Test Rig

- Flammability Test Rig

- 'LabVIEW' Instrumentation, PC Control & DAQ System

- Multi-purpose Aerospace Component Test Rig

Some of these ‘Case Studies’ are available on request.

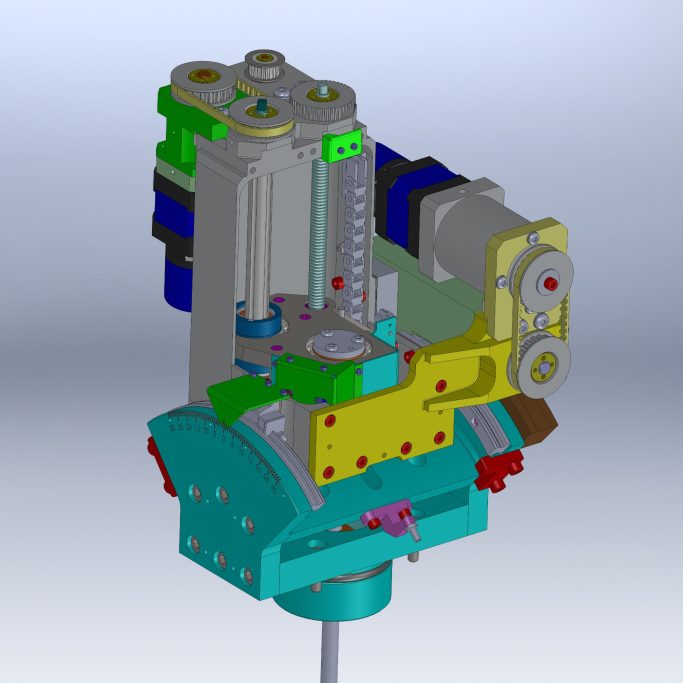

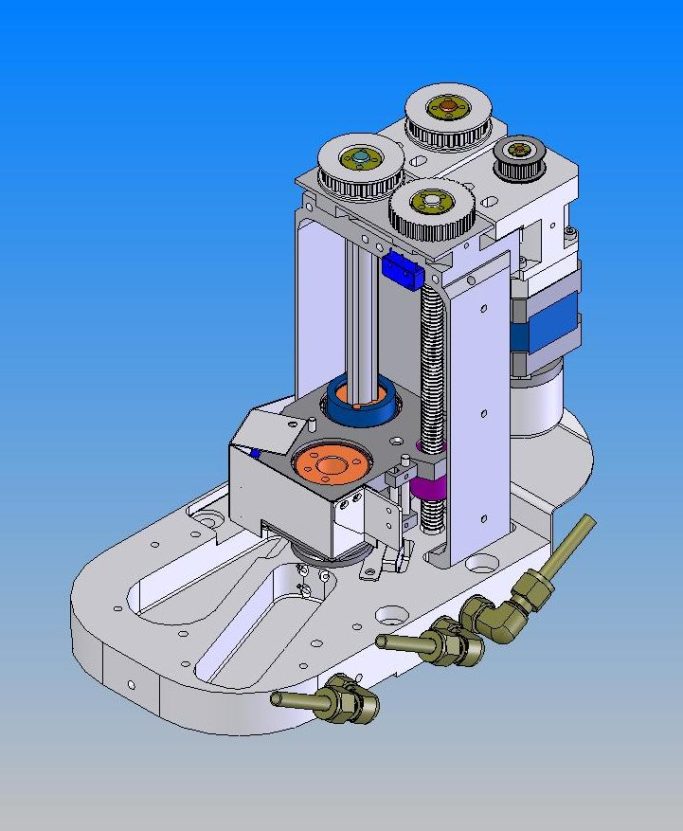

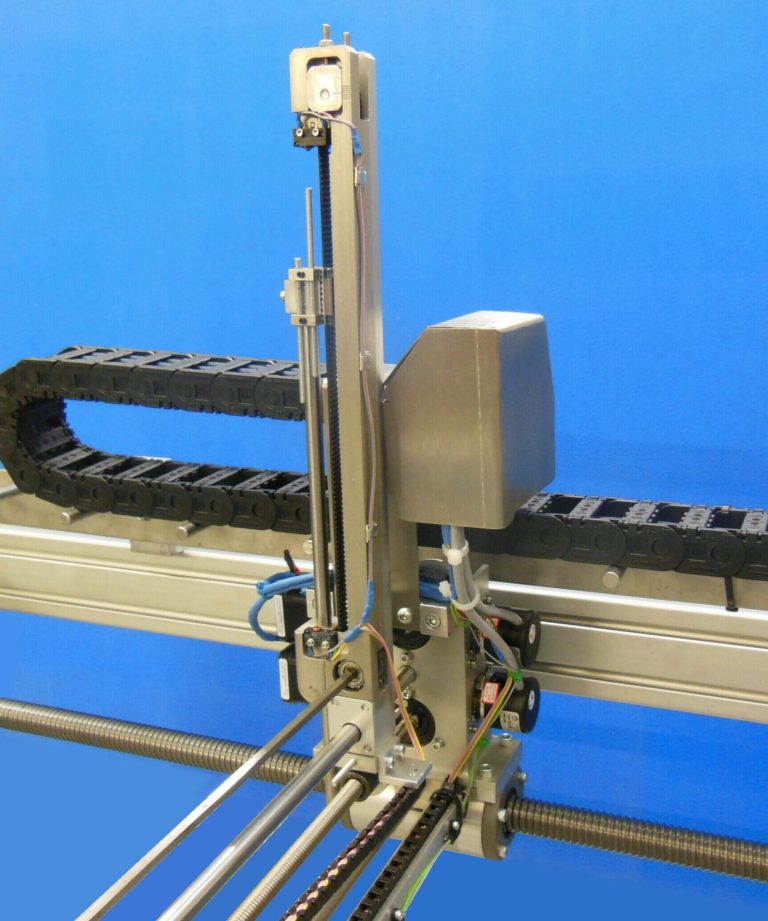

Traversing Systems

Based on our automation/robotic capability and structural design expertise, Sector Technology can offer a significant capability in the design and manufacture (D&M) of multi-axis traversing systems for specific applications. Some of these applications can use existing, OEM manufactured actuators, whilst for others, specific systems would designed and manufactured. For some particular applications, such as gas turbine and wind tunnel traversing systems, these are effectively multi-axis, special purpose robots, designed to be a high accuracy, high stiffness, lightweight design using advanced materials and high performance, lightweight, motor/gearbox drive systems. Typical applications and examples of Traversing Equipment and Systems are as follows are:

- D&M of Aerodynamic Probe Traversing Equipment

- D&M of Gas Turbine Probe Traversing Systems

- D&M of Instrumentation Calibration Traverse Eqpt.

- D&M of Automated Production Line Traversing Test & Assembly Equipment

- 12 Axis Neutron Detector Traversing Equipment

- Gas Turbine, 2 Axis Compressor & Turbine Test Rig Traversing System

- High Temp Aero Gas Turbine Compressor 2 Axis Traverse System

- Industrial Gas Turbine 1000 mm Range 2 Axis Traverse System, Non-ATEX & ATEX rated

- Model Turbine Probe, 3 Axis Calibration Rig

- Model Turbine Test Rig, 2 & 3 Axis Probe Traverses

- Model Turbine Circumferential Traverse System

- Model Turbine Exhaust Plenum 3 Axis Cartesian Probe Traverse

- Water Flume 5 Axis Rotary Traverse System

Some of these ‘Case Studies’ are available on request.

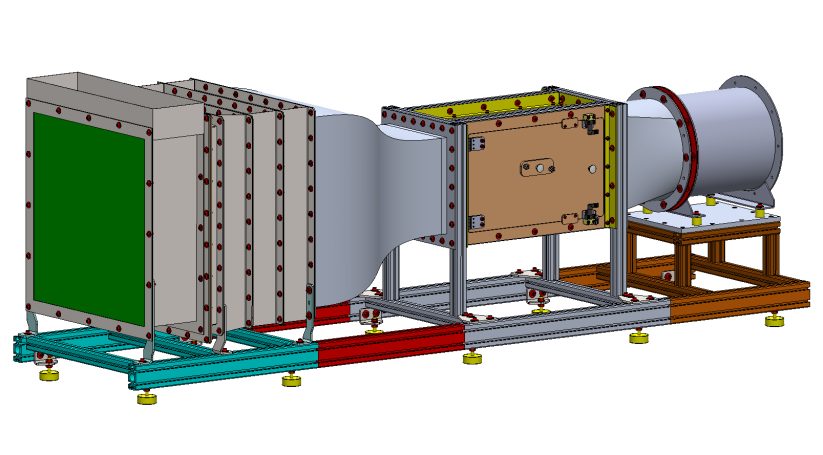

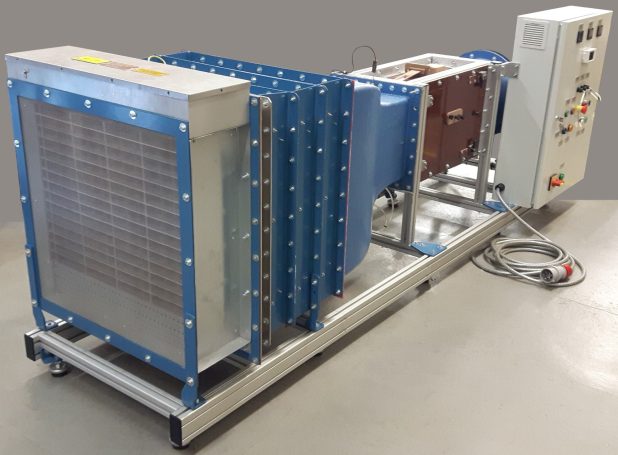

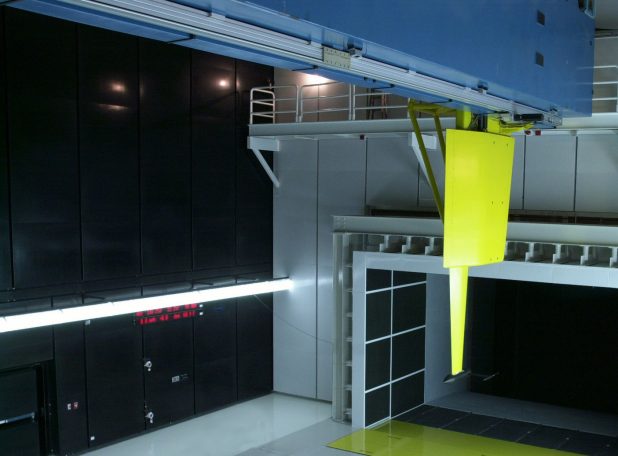

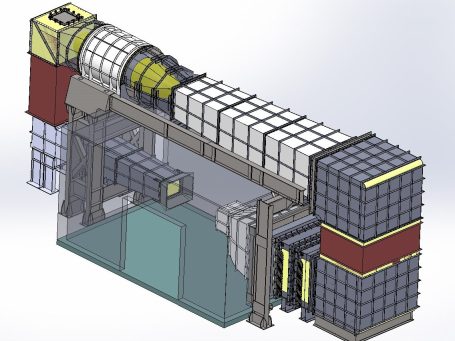

Wind Tunnels & Wind Tunnel Equipment

Sector Technology has a significant history of engineering experience and capability concerning the design and manufacture (D&M) of aerodynamic equipment for Wind Tunnels and Wind Tunnels themselves, based on our aerodynamic & elctro-mechanical design & analysis expertise. We have undertaken projects for a range of types and sizes of Wind Tunnels and Wind Tunnel Equipment, as shown in the examples below:

- D&M of Wind Tunnel Model Motion Systems

- D&M of Wind Tunnel Probe Traversing Systems

- Refurbishment of Wind Tunnel Balances

- D&M of Aero-acoustic Wind Tunnels

- D&M of Specialist Research Wind Tunnels

- Design of High Speed Wind Tunnels

- Testing of Wind and Water Turbine Test Rigs

- Wind Tunnel (WT) Multi-Model Motion System

- Floor Mounted WT Rotary Probe Traverse System

- Ceiling Mounted WT Rotary Probe Traverser

- Automotive WT Ceiling Mounted, 3 Axis Cartesian Probe Traverse System

- Wind Tunnel, 4 axis Rotary Probe Manipulator

- Wind Tunnel Sting Model Manipulation System

- Formula One Model Motion & Support System

- Hypersonic WT Model Traversing Systems

- Research WT 3 Axis Cartesian Probe Traverser

- 60 m/s Open Jet, Anechoic Chamber, Hybrid WT

- 80 m/s Open Jet, Aero-acoustic Wind Tunnel

- Specialist Low Velocity, Heated Inlet, Wind Tunnel

Some of these ‘Case Studies’ are available on request.

©Copyright Sector Technology Ltd. All rights reserved.

We need your consent to load the translations

We use a third-party service to translate the website content that may collect data about your activity. Please review the details in the privacy policy and accept the service to view the translations.